Weight Plates

Most bumper plate factories are located in specific industrial regions known for their manufacturing capabilities. Different regions may focus on various types of bumper plates, such as rubber, urethane, or high-end options. Understanding where your bumper plates are made can provide insights into their quality and cost.

Types of Bumper Plates

Types by Function

Training Bumper Plate: These plates are usually finished in black but also come in color versions with cool graphics. Training bumpers may use metal rings, making them thicker and more prone to warping.

Competition Bumper Plate: These plates conform to IWF specifications for size, tolerance, and color. They feature a solid steel core embedded into a rubber plate, reducing thickness by about 40%. Competition plates have a more dead bounce due to their higher durometer rating. These are considered some of the best bumper plates due to their superior quality, durability, and performance, making them ideal for serious weightlifters.

Technique Plates: Made from solid plastics like polyethylene, these plates are very light and ideal for beginners or rehabilitation training. They come in small weight increments and should only be used indoors on rubber flooring.

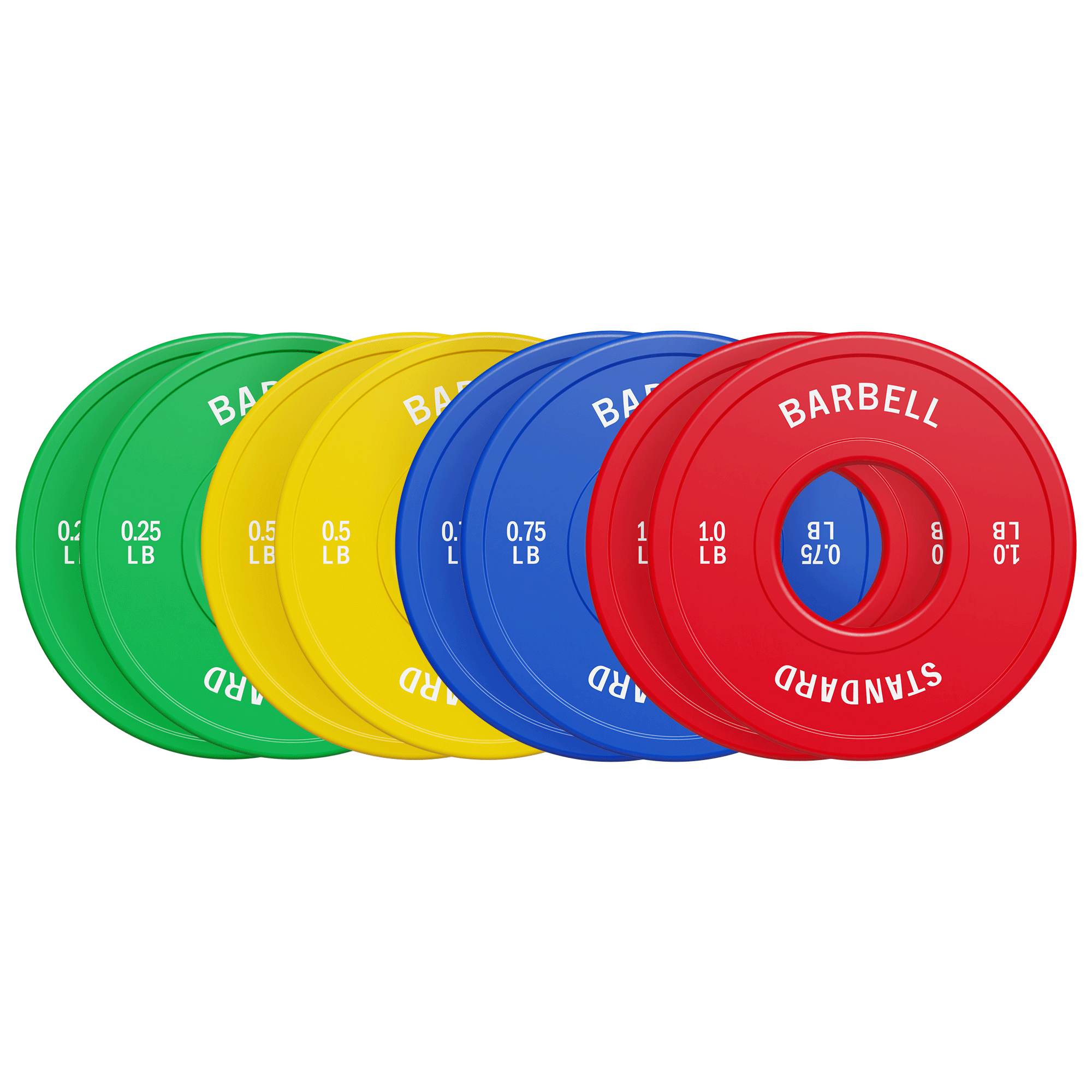

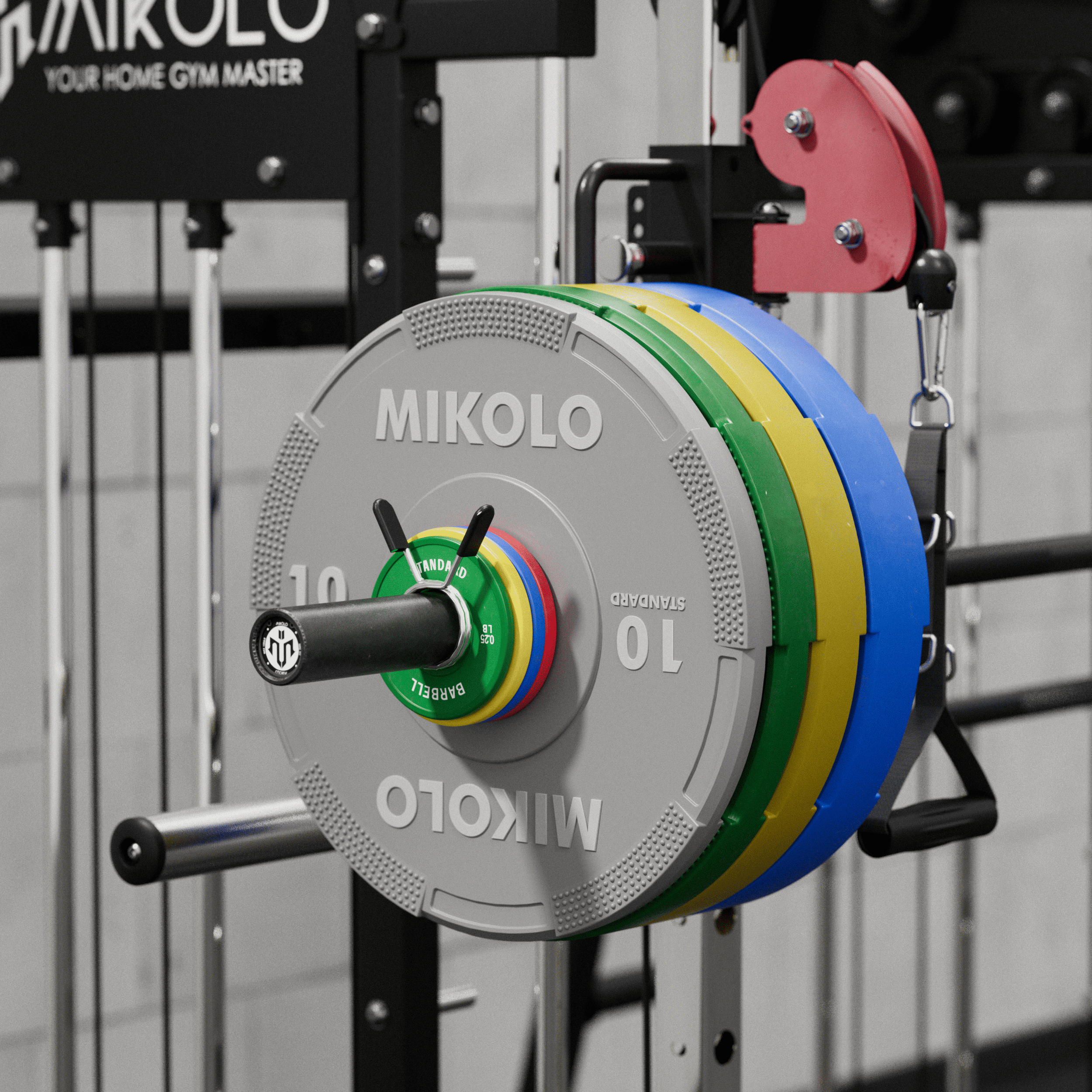

Change Plates and Fractional Plates: Change plates come in smaller increments (e.g., 0.5 kg, 1 kg) and are ideal for adding small weights. Fractional plates, with increments as low as 0.25 lb, are used for micro-loading during training.

Types by Material

Virgin Rubber: Denser and thinner with less bounce, virgin rubber plates are wear-resistant and have a milder odor. Solid rubber plates are known for their high durability and low noise features, lacking steel inserts or an iron core, and are precisely molded to enhance shock absorbent properties.

Crumb/Recycled Rubber: Made from ground recycled rubber, these plates are softer, cheaper, and have a higher bounce. They are less durable than virgin rubber plates.

Urethane: Combining properties of plastics and rubber, urethane plates are more durable, odorless, and come in bright colors. They are also thinner, allowing more plates to be loaded onto a barbell.

Bumper Plate Physical Structure

Plate

The quality of bumper plates and weight plates is largely determined by the materials used. Urethane is the best overall, followed by virgin rubber and then recycled rubber.

Steel Hub

Most professional bumpers have steel hub sections with a galvanized or chrome-plated finish. Avoid plates with brass hubs, as they are prone to bending and cracking.

Bumper Plate Physical Properties

Shape

Bumper plates should ideally be round with a lip on the edge for easier pick-up and to prevent collision and damage to the steel hub.

Weight

Bumper plates are available in kilograms and pounds, with weight tolerances typically within 2-3%. At Yanre Fitness, we offer plates with a guaranteed weight tolerance within +/- 1%. Our bumper plates are also available in pairs for different weight categories, ensuring you have the right quantity for your training needs.

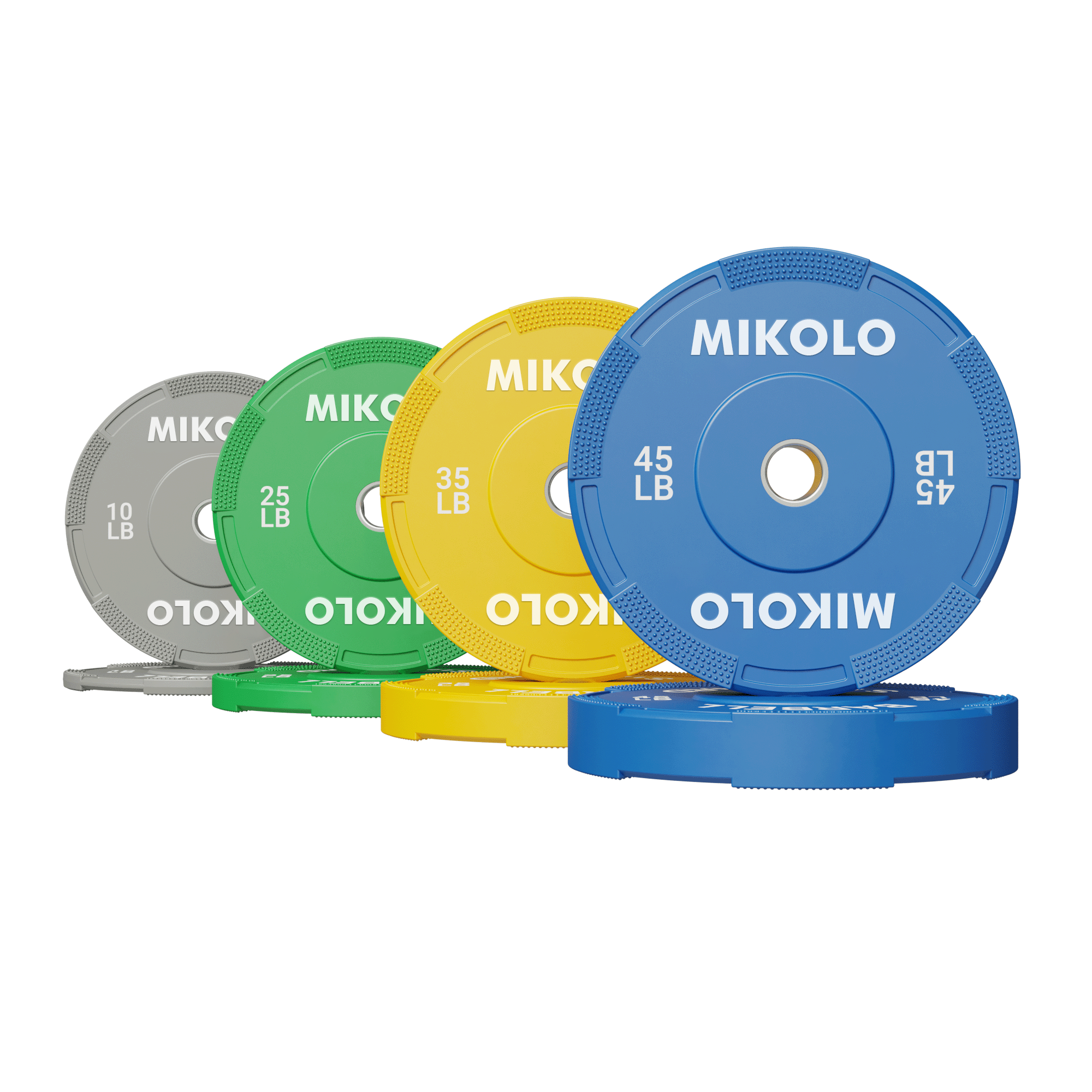

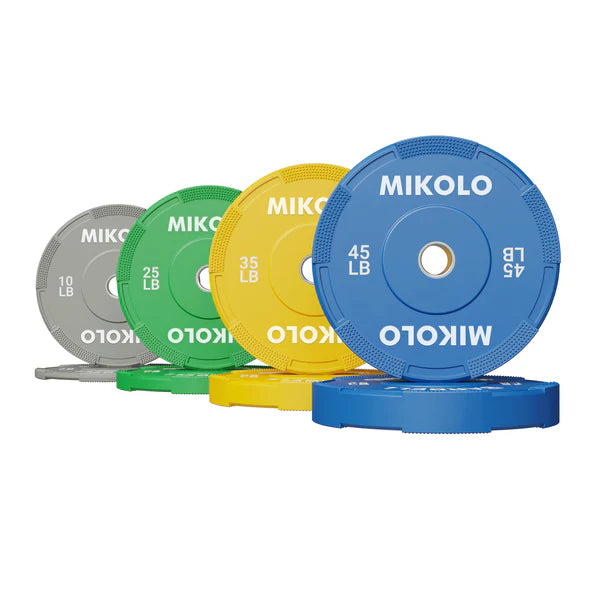

Color

Bumper plates are color-coded according to IWF standards to help differentiate between weights quickly and accurately. The color and raised lettering on these plates aid in easy identification, allowing users to quickly find the appropriate weights during training. Non-standard coloring should be avoided.

Noise

Rubber or urethane materials in bumper plates absorb impact, reducing noise compared to steel plates.

Odors

Virgin rubber has a milder odor compared to recycled rubber. Urethane plates are completely odorless.

Bounce, Hardness, and Durability

The Shore hardness scale is used to judge the material hardness. Plates with higher Shore ratings have less bounce and greater durability. These characteristics make them ideal for Olympic lifts due to their reduced bounce and increased durability.

Bend

Poor quality rubber can cause plates to bend, producing an uneven load. This is a common issue with thin, small plates.

Buying Tips and Traps to Avoid

Material: Avoid manufacturers using inferior rubber or impure urethane. High-quality bumper plates are essential for achieving fitness goals, ensuring durability and safety during strength training.

Weight Accuracy: Opt for plates with a weight tolerance of +/- 1% or less.

Warranty: Good bumper plates should have at least a one-year warranty. Additionally, signing up for the newsletter can provide a discount on the first order, adding extra value to your purchase.

Width & Diameter: Plates should be close to 450 mm in diameter and have a collar opening of 50.4 mm.

Color Coding Accuracy: Ensure the weight matches the IWF standard and the coloring is even.

Printed or Raised Letter: Raised lettering is more durable than printed words.

Steel Hub: Choose hubs made of steel or stainless steel with chrome-plating or zinc-plating finishes.

Drop Test: Check the maximum number of drops the plate can withstand.

Conclusion

Choosing the correct bumper plate type can be a challenging task. We hope that the valuable insights provided in this article have armed you with the knowledge you need to make the right buying decisions. Bumper plates are essential for learning and practicing Olympic weightlifting techniques, and their development is closely tied to the sport of Olympic weightlifting.